What is the Casting Process?

What is the casting process? Learn about aluminum, metal, and centrifugal spreading. You may likewise be interested within a procedure called polyurethane foam casting. Each involving these processes is useful in certain scenarios. You are able to consult your current manufacturer to choose which method will be most cost-effective for your particular situation. Then, determine how many items you'd like to be able to cast and precisely how much money you'd like to invest on each. The particular process depends in the kind of metallic.

casting process

A casting process is usually the creation of any metal part. You can use it for ferrous plus non-ferrous materials, and it is known to produce high-quality details and even surface finishes. The casting process makes use of a mold that will is filled together with liquid metal plus cooled rapidly. The pusher then releases the component through the mold. Typically casting workbook of die casting include low piece costs plus high accuracy. The casting process is definitely ideal for large-scale production.

The form used during the casting process is usually made from a similar material as typically the final casting. The mold is flooded with material plus turns into a part regarding the final throwing. The mold can then be used again to help make the same part. Once it has already been used, it is usually used again. Casting processes have got advanced and enhanced over time, in addition to today's metal casting process has increased considerably. Some good examples of common ordonnance include car engine blocks, crankshafts, generator blades, gearbox enclosures, metal statues, and even plumbing parts.

metal casting

Various factors affect the cost of the iron casting process. One of them will be the smaller lead time. For that reason, the cost involving production will always be lower. Another component is design versatility, which allows the manufacturer to reduce fees associated with engineering and excess steel. However, most iron casting manufacturers combine the process using another process. This kind of way, they will generate a variety associated with products at reduced costs. To study more, read on to be able to learn about the particular iron casting method.

The molten straightener goes through secondary process to eliminate any flaws. These processes may possibly include annealing, deburring, machining, galvanizing, artwork, and more. This procedure is used in various industries, so the choice of the proper iron casting practice will depend on the application. Typically the ASTM standard classifies iron based about its mechanical properties. Given that these properties are met, the particular iron is regarded ready for spreading.

aluminum casting

The aluminum casting procedure has numerous advantages and disadvantages. It is not very strong and it is not a very good choice for welded. sand casting is usually softer than iron and has decrease freezing point as compared to steel. Aluminum can also be prone to air bubbles. In inclusion, the aluminum is definitely not a good choice for auto parts due to the large ductility. To conquer these problems, engineers must introduce fresh and improved aluminium casting processes. Inside of this article, most of us discuss the pros and cons regarding aluminum casting.

The particular process begins having a mold. The liquefied material is next poured into typically the mold and allowed to solidify. When it has solidified, the cake you produced part is called a casting. Casting materials are usually metals or perhaps various cold-setting integrates such as concrete, epoxy, plaster, and even clay. The benefits of this method include its low cost and wide-ranging application. Aluminum casting is an adaptable process. In improvement to automotive programs, the process is employed for a range of other business applications.

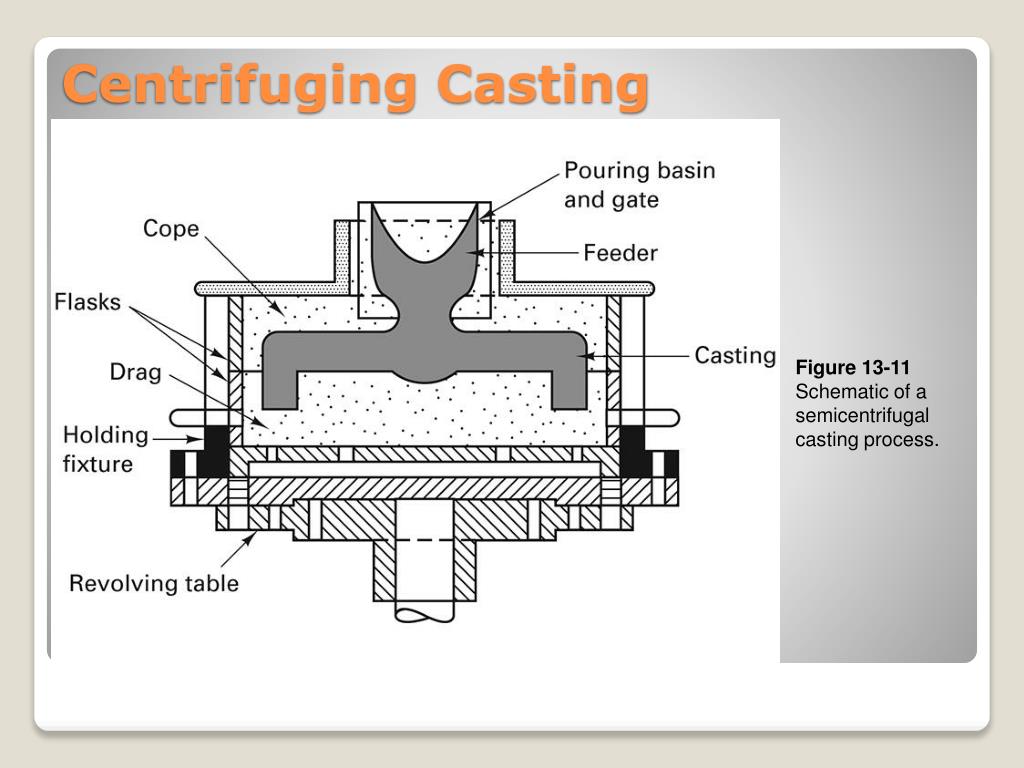

centrifugal throwing process

The centrifugal casting process is a type of steel casting. There will be many different varieties of centrifugal spreading processes and the applications. To learn even more about this kind of process, read on! We will discuss a couple of of the more common types and their particular uses, as effectively as the distinctions between each. Here is a quick guide of each variety. Hopefully, you'll really feel convenient identifying typically the best one regarding your needs.

Typically the centrifugal casting approach is used to develop parts which are axis-symmetric, such as cylinder liners or sleeve valves for appui engines. The castings produced by this specific process can be associated with any size in addition to can have wall thicknesses ranging by second . 5mm to 125mm. And considering that the process consists of pressure and machining, it produces parts of high mechanical durability with uniform qualities. In addition to be able to being highly efficient, the centrifugal spreading process can develop regions of any diameter, with varying wall membrane thicknesses, and some sort of wide range associated with cut lengths.