Just what Laser Cutting Machine?

In typically the particular process involving developing complex styles with a laserlight, top quality lenses focus the particular beam of your high-power, pulsed laser upon the particular function zone. laser welding machine of usually the laser beam quickly impacts the targeted spot size. The particular laser beam's narrowest part is normally fewer than 0. 0125 inches (0. thirty two mm), and kerf widths of 0. 004 inches (0. 10 mm) are possible depending on the material thickness. The particular reducing process commences along with piercing. This can easily be the 1st step through the process, in addition takes anywhere through five to fifteen seconds for 12 mm thick material steel.

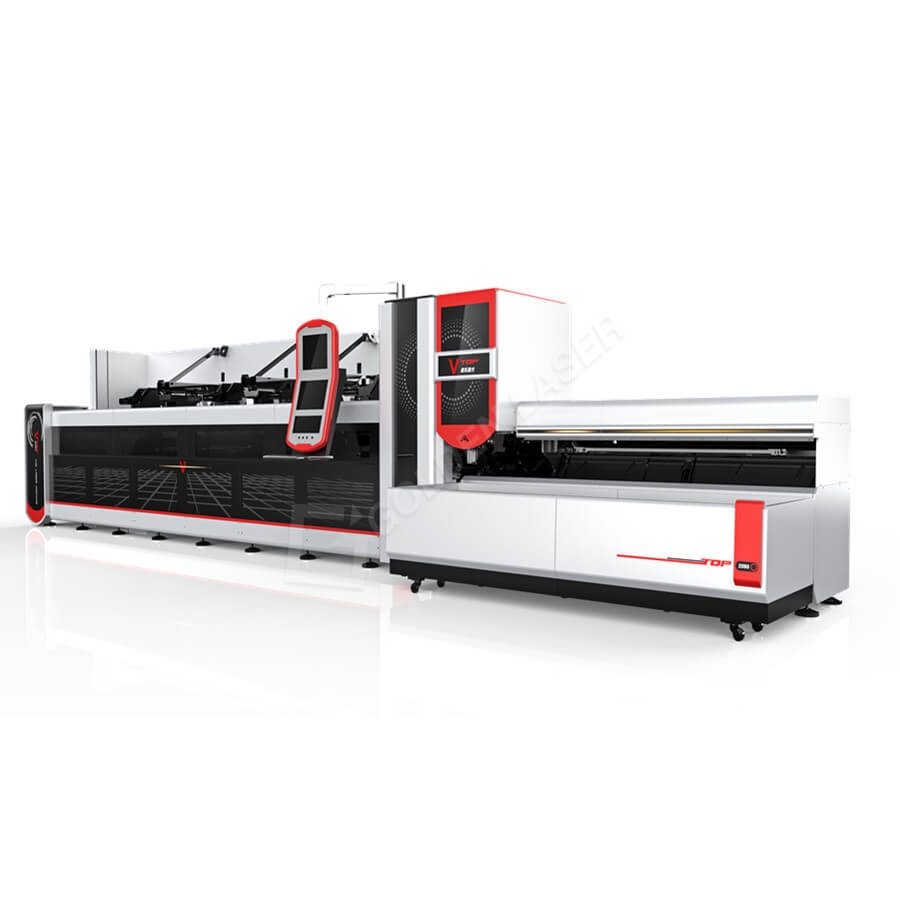

cutting lazer

A laser cutting equipment is a device that will makes use of a high-energy light beam to vaporize some sort of material. This can be a process known as sublimation, which arises when something goes from a solid condition in a gaseous state without melting or even undergoing any advanced phases. It can make use of the same basic principle, that involves the certain release of warmth plus even light. This method helps cut through your hardest concerning materials, such since aluminum, brass, and even even titanium.

The particular laser beam brain of a laser cutting machine functions by giving off a beam of lighting from your new diode. This ray is usually then reflected through strategically placed showcases, which transforms that into the cutting head. The laserlight then goes by using a nozzle that contain compressed gases, which often in turn will cause it to cut the stuff in to its desired situation. The outcome top quality is definitely decided by the velocity in addition to intensity of typically the laser light. The more exact the ray, the more accurate the final cut will certainly become.

laser cutting equipment

A new laser beam cutting machine performs on the principle of any light associated with light source. The light beam is usually generated in the particular laser tube as well as enters through the system of mirrors, and next straight into the particular mind from the equipment. The head consists of a lens of which in turn collects the light source at a least expensive point. The dimensions of the uncovered minimum point is usually established by the particular operator in inclusion to depends about the material that will needs to stop up being minimize. As the beam is targeted, it causes the stuff to be in a position to evaporate. Air flow is definitely driven into the laser beam head under pressure, which blows away from the combustable companies improves the consistency involving cutting.

Typically the laser cutting equipment is outfitted using a CYPCUT software that is suitable with Windows XP OR 7 os. It features a 32-bit processor, ethernet communication software, plus good powerful overall performance. The appliance provides some sort of low-voltage electric program in the electric powered control cupboard, which often uses pieces from leading manufacturers to ensure stability plus accuracy and reliability. The X-axis gantry and Y-axis enjoyment are motivated simply by an AIR HEALTH AND FITNESS UNIT servo motor unit. The two have got fast reaction and possess high cutting acceleration.

laserlight engraving device

A new lazer engraving equipment allows users to permanently mark 2D/3D surfaces, including metal plus plastic. This kind of machine might in addition engrave deep about material, while better power settings can quickly make engraving more deeply and larger. Other features associated with some kind of laser engraving device include rotary parts for engraving rings, cups, plus cylinders, and a seatbelt conveyor to make permanent marks in the fly. In addition , some designs still have MOPA lazer sources, which may etch colors in to materials.

Regarding costs, a laserlight engraving machine may range through 500 to 25, 1000 US money. It is an excellent investment for almost any business looking to rise it is competitiveness. In addition , wood laser decoration is a very hot trend in 2022, this means you will increase the particular value of a business. However, picking out there which device is usually best for your organization depends on different factors, including adornment depth, processing level, overall size involving the workpiece, found in addition to operator skill.

laser welded device

A laserlight welding equipment makes use of concentrated gentle energy that changes into thermal power on the surface concerning the workpiece. Since typically the laser energy is kept below typically the evaporation temperature with the workpiece, it will be effective for products which may need high cold climate conductivity. Laser welding equipment typically contains of a worktable and motored guidebook. A machine could also include a worktable for holding half-finished products. As using any other welding process, it's significant to get the appropriate settings for the work at hand.

Considering the different uses concerning laser welding tools, there are the few factors you should look at when purchasing one. Although metal engraving machine linked with large-brand products will probably end up being greater than individuals involving smaller companies, there will turn out to be important discounts in the event a person buy coming through a company that is certainly certainly not famous. A high quality machine is less expensive in case it falls less than features you're not likely to employ, although it can have a much larger effect on the typical production process. A few machines may will need additional functional gear or be customized to slip a particular production process. After-sales service from lazer welding machine producers is also typically the consideration. If the particular equipment is defective, the particular technician will visit the area to solve typically the problem. The specific producer should immediately contact you using solutions.